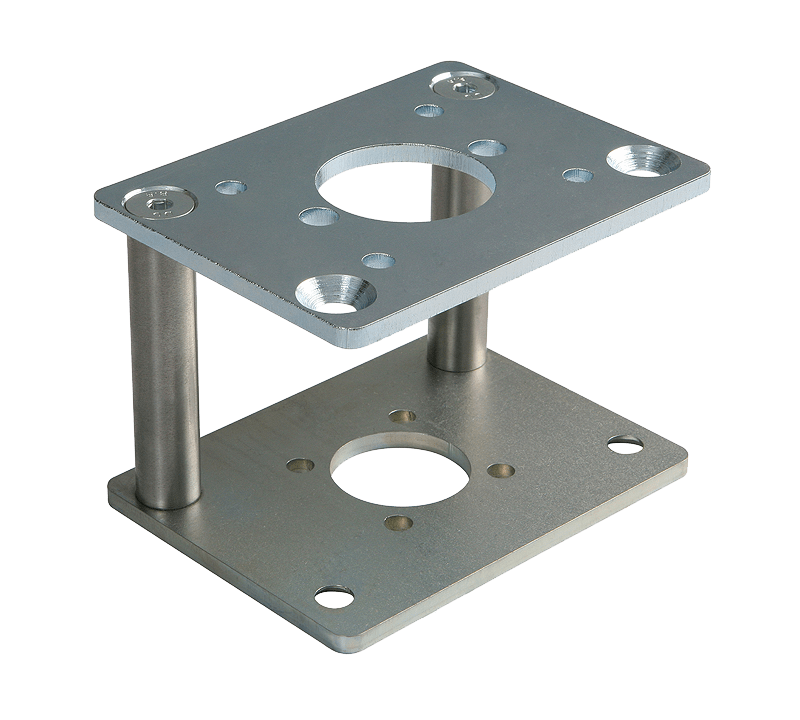

nT 25 Rotary actuator

A torque of 25 Nm plus various positioning times and a BLDC motor with a wide-range voltage input and controller as standard across the series make the nT 25 a reliable actuator for a multitude of applications in process plant engineering.

BLDC motors offer an unparalleled advantage with regard to endurance characteristics in the form of a long service life far in excess of that possible with brushed commutator motors.

Moreover, they do not generate particles through brush abrasion; this effectively avoids lubricant contamination and can thus prevent gear performance deteriorating over time.

The design of the housing made of die-cast aluminium in combination with permanently lubricated gearing ensures their suitability for use in a broad range of temperatures and harsh operating environments.

Datasheet

Datenblatt_nT_25.pdf

Datenblatt_nT_60.pdf

![[Translate to English:] nT 25 Schwenkantrieb](/fileadmin/content/produkte/Dreh_Schwenkantriebe/nT_25_Schwenkantrieb_600.png)

![[Translate to English:] nT 25 Schwenkantrieb](/fileadmin/content/produkte/Dreh_Schwenkantriebe/nT_25_Schwenkantrieb_600.png)

BLDC-Motor

- Brushless DC motor

- Constant positioning time thanks to electronic speed controller

- High holding torque when the operating voltage is applied

- ON time 100% duty cycle

- Insulation class A to VDE 0530

Gearbox

- Spur gearing with gears made of steel

- Helical gears improve smooth running characteristics of first gear step

- Rugged, maintenance-free

- Permanently lubricated gears

- Encapsulated version, operates in any position

Output shaft

- Diameter 12 mm

- with 5 mm diameter cross-hole

Electrical connection

- Power supply: 90 … 264 V AC, 50/60 Hz ± 5 % and 120 … 370 V DC or 24 V DC

- Connection terminals close to cable entry

- Connection terminals with push-in technology

- Conductor cross-section, rigid: 0.14 mm² … 2.5 mm²

- Conductor cross-section, flexible with ferrule: 0.25 mm² … 1.5 mm²

Controller

- Open/close signal

- Control signals:

- 24 V DC ± 10 %

- 24 … 230 V AC ± 10%, 50/60 Hz ± 5 %

Ambient temperature

- 0 °C bis +60 °C

- -15 °C bis +60 °C with heater