NEx-K Linear actuator

The NEx-K linear actuator for Ex zone applications is a further development of the flameproof housing of the NEx rotary and part-turn actuator with Ex Zone 1 marking CE2004 EX II 2G Ex d IIC T6 Gb, based on IECEx certification IECEx EPS 15.0061X and ATEX certification EPS 15 ATEX 1 044 X.

NEx series linear actuators are used to precisely adjust dampers in all air-conditioning, ventilation and heating systems as well as in furnace installations, process plant engineering and other fields of industry. They are available with actuating forces of 400 N - 5000 N.

The stroke units are designed for stroke lengths of 150 - 750 mm. The technical construction mirrors that of series NEx actuators.

Datasheet

Datenblatt_NEx_K.pdf

Datenblatt_NEx_K_DC.pdf

![[Translate to English:] NEx-K Linearantrieb](/fileadmin/content/produkte/IECEx_ATEX%20/05_2019/Nex_K_600_650.png)

![[Translate to English:] NEx-K Linearantrieb](/fileadmin/content/produkte/IECEx_ATEX%20/05_2019/Nex_K_600_650.png)

Housing

- Housing and hood are made of corrosion-resistant gravity die-cast aluminium

- Coating with silicone-free paint

- Colour RAL 7032 Pebble Grey

- The motor compartment is designed as a type “d” flameproof enclosure to DIN EN 60079-1

- Degree of protection IP66/67

- Options:

- Custom colours

Synchronous motor

- Single-phase AC synchronous motor with permanent magnets, reversible

- 230 V ± 10%, 50/60 Hz ± 5 %

- ON time 100% duty cycle on request

- Short start/stop times

- Insulation class B to VDE 0530

- Synchronous motors maintain speed and positioning time irrespective of the load

- Options:

- Custom voltages

- Custom frequencies

BLDC motor

- Brushless DC motor

- Constant positioning time thanks to electronic speed controller

- Wide-range voltage input 90 V AC … 264 V AC, 120 V DC … 370 V DC

- High holding torque when the operating voltage is applied

- Manufacturer configured start-up and brake ramp

- ON time 100% duty cycle

- Insulation class B to VDE 0530 DC motor

DC motor

- DC commutator motor

- Voltage 12 V DC or 24 V DC

- Insulation class E to VDE 0530

Gearbox

- Spur gearing with straight-toothed steel gears

- robust, wartungsfrei

- Rugged, maintenance-free

- Permanently lubricated gears

- Self-lubricating sintered bronze bearings

Stroke unit

- Fixing bracket made of die-cast aluminium

- Spindle made of stainless steel

- Spindle self-locking

- NNeedle bearings to absorb axial forces

- Steel and bronze materials for good anti-seizure properties

Spindle

- Self-locking

- “Open/closed” markings indicate position

- Made of stainless steel

Electrical connection

- Connection by means of 1 m cable end or Ex “e” rated terminal box with spring-loaded terminals

- Customer-side wiring outside of the flameproof housing

- Electric anti-condensate heater

- Manual reset temperature switch 80 °C

Controller

- Open/close signal

- Options:

- Additional potential-free contacts

- Electronic position controller ESR-N with Profibus and USB interface for synchronous motors

- Potentiometer 200Ω … 10 kΩ

- Blocking protection by monitoring changes to the actual value of the potentiometer (only in conjunction with position controller ESR-N)

Ambient temperature

- -20 °C to +60 °C

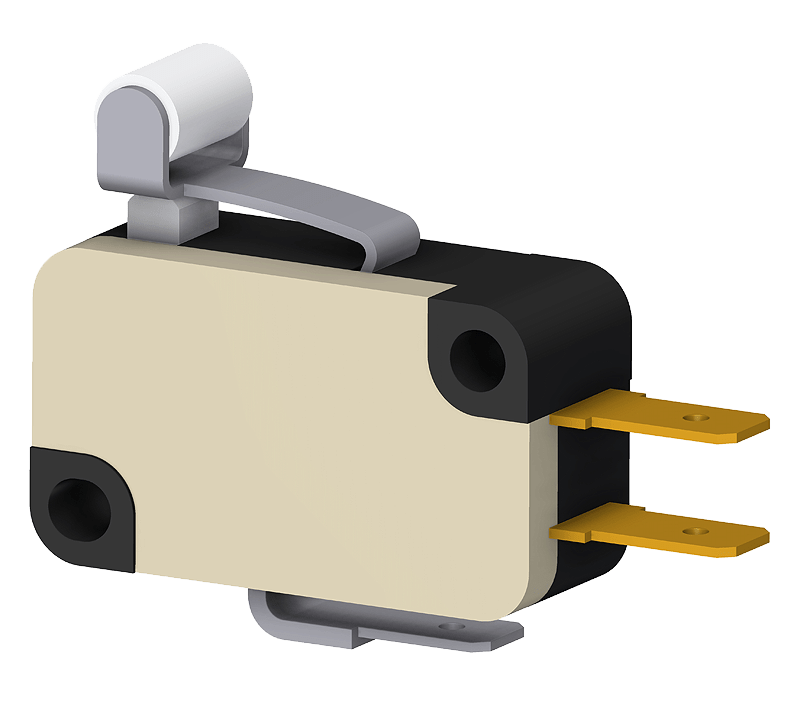

Angle of rotation limited by snap-action position off switch

- Changeover switches with silver-plated contacts

- Switch connections routed to terminals

- Switching capacity: max. 6 A, 250 V AC

- Options:

- Switches with gold-plated contacts

- Switches with positive-break contacts

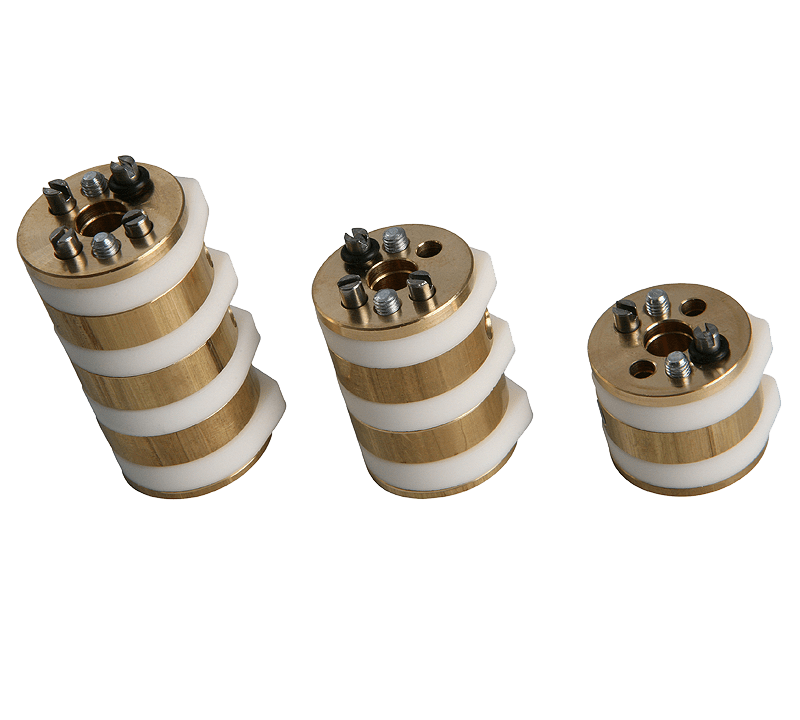

Position sensor for external position indication (optional)

- With potentiometer

- Conductive plastic potentiometer (standard) or wire-wound potentiometer (including TÜV approval)

- Multiturn potentiometer up to 10 turns

- Gearing makes it easier to adapt the electrical angle of rotation of the potentiometer to the desired angle of rotation of the actuator

- Special potentiometers with TÜV-approved form-fit attachment solution are available for electronic fuel/air ratio control

- With 4 ... 20mA transmitter

- Gearing makes it easier to adapt the electrical angle of rotation of the transmitter to the desired angle of rotation of the actuator

- With Hall sensor

- The wear-free absolute encoder that makes use of the Hall effect is particularly suitable for continuous operation in potentially explosive atmospheres

Manual operation (optional)

- The position of the input shaft and valves can be moved manually using a handwheel

- Disengaging the gear train and motor reduces the amount of force required

- Position switch-off settings are retained during manual operation

- The handwheel remains motionless during electrically powered operation

Options

- Other voltage/frequency

- Handwheel

- Additional auxiliary position switches

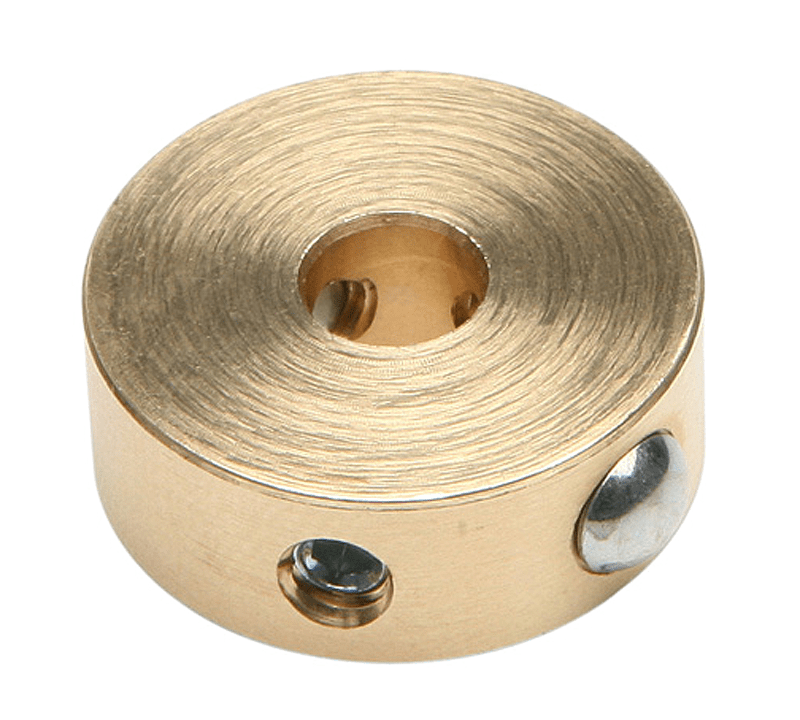

- Custom control cams

- Electronic position controller ESR-N (in conjunction with synchronous motor)

- Position sensor

- Relay for switching several actuators in parallel

- Potentiometer

- Components to UL standard

- Spindle protected by bellows

- Set collars serve as external travel stops

Assembly

- Easily mounted thanks to stable cast angle bracket and steel angle section attached to housing

- Connecting pin supplied to connect spindle with valve

- No-fuss coupling to valve stem by means of:

- Lever arm, clamping lever, ball-and-socket joint, connecting rods, sprung connecting rods

Safety instructions

- In a potentially explosive area, ensure the device is isolated from the power supply before the hood of the flameproof encapsulated housing is opened by a specialist. The waiting time specified on the rating plate must always be observed!